| SEALING SPEED | 800~900 / PER HOUR |

| CARTON DIMENTION (W) | 150mm~ -500mm |

| CARTON DIMENTION (H) | 120mm~ 500mm |

| CARTON DIMENTION (L) | 200mm~600mm |

| TAPE APPLICABLE | 48~60~75W x 1000ML |

| TABLE HEIGHT | 570 ~770 mm (ADJUSTABLE) |

| DIMENSION | L1880 x W900 x H1510mm |

| WEIGHT | ≈180Kgs |

| NOISE DEGREE | MAX: 80dBA |

| ELECTRIC CONSUMPTION | MAX: 0.2KW |

| VOLTAGE USAGE | 220V/50Hz/60Hz/1Ph |

| PNEUMATIC USAGE | 380V/50Hz60Hz3Ph ; 3kgf /cm² 100nl/min |

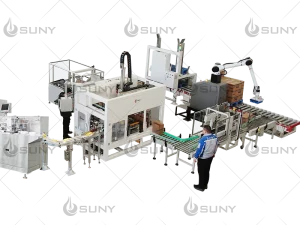

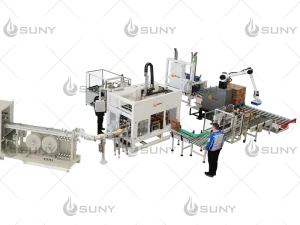

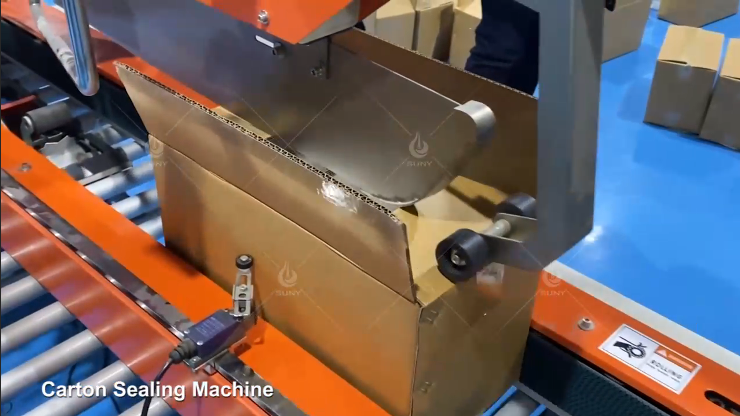

Carton Sealing Machine

SEALING SPEED

800~900/h

Multiple Specifications Support

Carton width and height can be flexibly adjusted, allowing for a wide sealing range.

Double-drive sealing

The upper and lower sealing actions are completed at one time, which makes the sealing faster and the bonding stronger.

This fully automatic Carton Sealing Machine features dual-drive upper and lower sealing for fast and secure sealing. Flexible manual adjustment of carton width and height allows for flexible adaptation to various sizes. High sealing speed and wide applicability.