In today’s hyper-competitive manufacturing world, end-of-line automation is no longer optional—it’s a survival strategy. Rising labor costs, higher output demands, and tighter delivery schedules are forcing factories to rethink how products are packed, boxed, and palletized.

That’s where Chinapack Intelligent comes in.

As a professional manufacturer of case packing lines, secondary packaging machines, and palletizing robots, Chinapack Intelligent has become a trusted automation partner for manufacturers worldwide. But with so many automation suppliers on the market, a fair question arises:

Why choose Chinapack Intelligent for case packing lines and palletizing robots?

This article breaks it down clearly, practically, and honestly—covering real buyer concerns, common questions, and the tangible value Chinapack Intelligent delivers on the factory floor.

1. A Complete End-of-Line Automation Specialist (Not a One-Machine Seller)

One of the biggest reasons manufacturers choose Chinapack Intelligent is its system-level thinking.

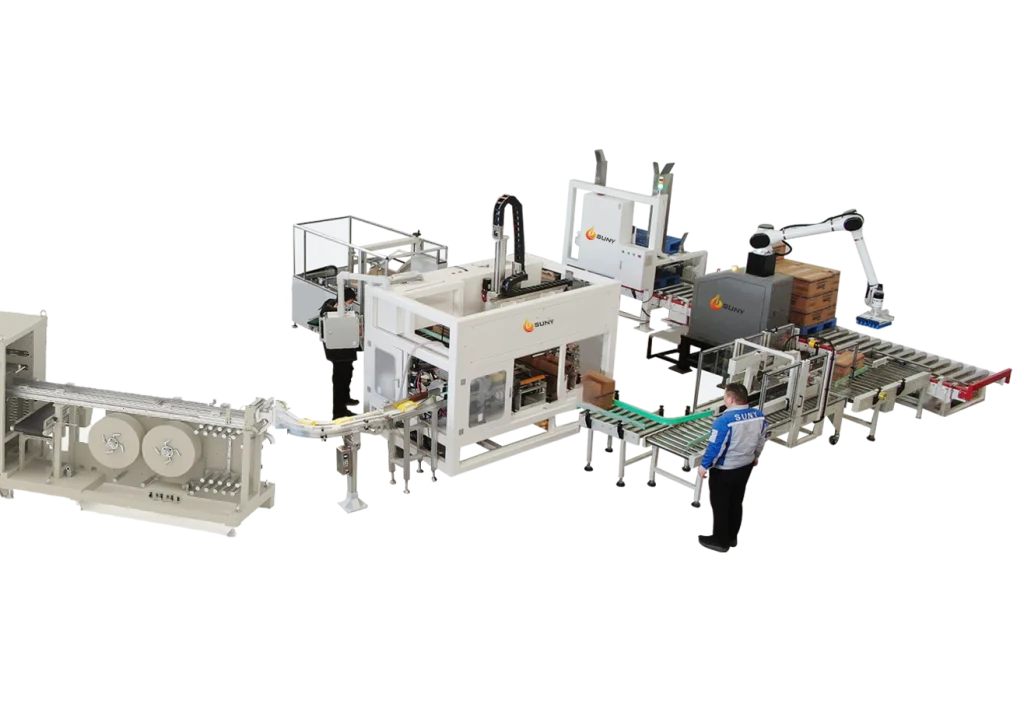

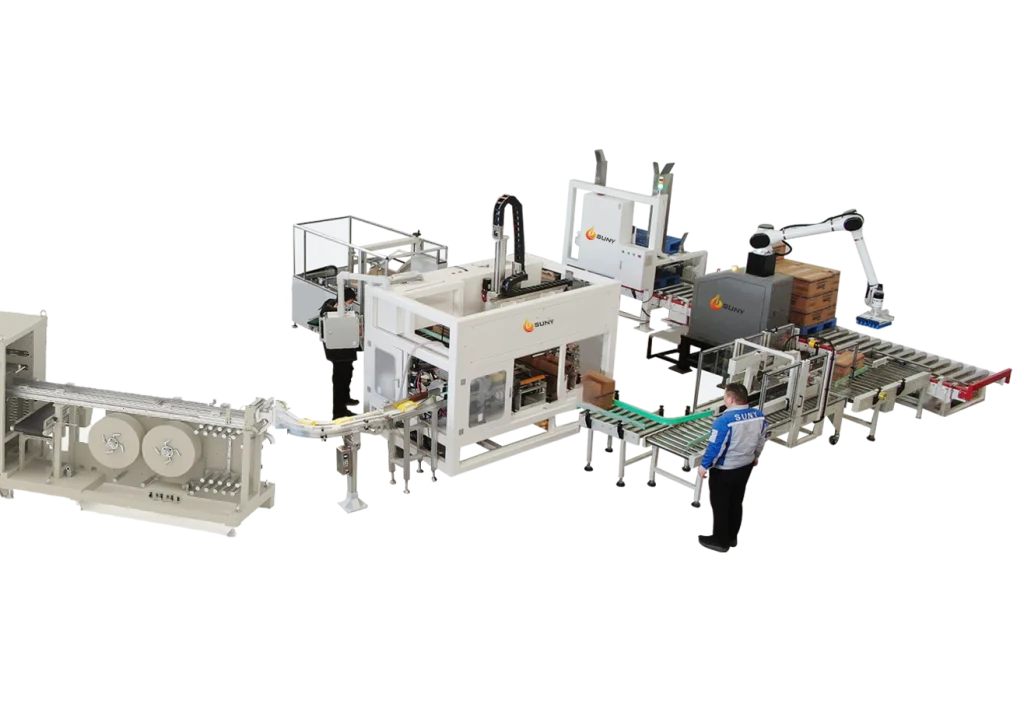

Instead of selling isolated machines, Chinapack Intelligent designs complete secondary packaging and palletizing systems, including:

- Automatic case packers

- Carton forming and sealing machines

- Conveying and accumulation systems

- Robotic palletizers

- Pallet dispensers and stretch wrappers

This integrated approach eliminates compatibility issues, reduces commissioning time, and ensures every component works seamlessly together.

Result: Faster installation, smoother operation, and fewer production headaches.

Why Choose Chinapack Intelligent for Case Packing Lines and Palletizing Robotstissue solution main

2. Proven Expertise in Case Packing Lines

- Case packing is not just about putting products into boxes—it’s about speed, accuracy, and product protection.

- Chinapack Intelligent offers multiple case packing solutions, including:

- Pick-and-place robotic case packers

- Top-load and side-load case packing machines

- High-speed case packing lines for continuous production

These systems are engineered to handle diverse product types—from bags and bottles to cartons, cans, and irregular items—without sacrificing efficiency.

According to industry data, automated case packing can reduce packing labor costs by up to 60% while improving consistency and output stability.

3. Advanced Palletizing Robots Built for Real Factories

Palletizing robots are only valuable if they perform reliably under real production conditions—not just in brochures.

Chinapack Intelligent palletizing robots are designed with:

- High payload capacity

- Flexible gripper solutions

- Multi-pattern palletizing capability

- Compatibility with multiple pallet sizes

Whether for food, chemical, daily-use products, or industrial goods, Chinapack Intelligent palletizers help manufacturers increase palletizing efficiency by 2–3 times compared to manual labor.

4. Customization That Actually Solves Problems

One-size-fits-all rarely works in packaging automation.

Chinapack Intelligent stands out for its deep customization capabilities, including:

- Line layout optimization for limited factory space

- Product-specific gripper and carton designs

- Speed matching with upstream production lines

- Adaptation to local standards and power requirements

This customization ensures the automation line fits your factory, not the other way around.

5. Smart Automation Focused on ROI

Automation investments must pay back quickly.

Chinapack Intelligent designs its case packing lines and palletizing robots with return on investment (ROI) as a priority. Typical customers achieve:

- Payback periods of 12–24 months

- Reduced labor dependency

- Lower error and rework rates

- Improved production predictability

By balancing performance, durability, and cost control, Chinapack Intelligent delivers practical automation—not over-engineered excess.

6. Frequently Asked Questions (FAQs)

Is Chinapack Intelligent suitable for small and medium factories?

Yes. Chinapack Intelligent offers modular and scalable solutions, making automation accessible even for factories with limited budgets or lower production volumes.

Can one line handle multiple products?

Absolutely. Many Chinapack Intelligent systems are designed for quick changeovers, allowing one line to pack and palletize multiple SKUs efficiently.

How reliable are the machines?

Chinapack Intelligent uses industrial-grade components and proven mechanical designs, ensuring stable 24/7 operation in demanding environments.

What about after-sales support?

Chinapack Intelligent provides installation guidance, remote technical support, and long-term service support to ensure continuous performance.

7. Global Project Experience Across Industries

Chinapack Intelligent has supplied automation solutions for:

- Food and beverage manufacturers

- Chemical and daily chemical plants

- Consumer goods factories

- Industrial product producers

This cross-industry experience allows Chinapack Intelligent engineers to anticipate real-world challenges—from dusty environments to unstable packaging materials.

Choosing the right automation partner can define your factory’s competitiveness for the next decade.

With its system-level expertise, proven case packing lines, reliable palletizing robots, and customer-focused engineering, Chinapack Intelligent offers more than machines—it delivers confidence, efficiency, and growth.

If you’re planning to upgrade your secondary packaging or end-of-line automation, Chinapack Intelligent is a choice built on performance, practicality, and long-term value.