The global demand for tissue products—from toilet rolls and facial tissues to kitchen towels—is reaching unprecedented levels. For manufacturers, keeping up with this demand means running production lines faster and more efficiently than ever before.

However, a bottleneck often occurs at the very end of the line: Palletizing.

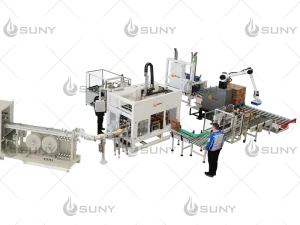

Manual stacking is no longer viable for high-speed modern factories. This is why forward-thinking manufacturers are rapidly adopting Robotic Palletizing Systems.

1. Gentle Handling for Delicate “Soft Packs”

Unlike rigid boxes of canned goods, tissue products are soft, lightweight, and easily deformable.

The Challenge: Human workers or traditional mechanical stackers can easily crush the packaging or damage the product if the grip is too tight.

The Robotic Solution: Modern palletizer robots are equipped with specialized End-of-Arm Tooling (EOAT). whether it’s servo-driven grippers or vacuum suction pads, these robots can handle soft packs with extreme precision. They apply just enough pressure to lift the bundle without compromising the product quality or the secondary packaging appearance.

2. Keeping Up with High-Speed Production Lines

Tissue manufacturing lines are notoriously fast. A high-speed Case Packer upstream can churn out dozens of bundles per minute.

- The Reality: Even the fastest human workers cannot maintain the pace of a modern rewinder and packaging line for an 8-hour shift without fatigue.

- The Efficiency Gain: A palletizer robot operates 24/7 with consistent speed. It eliminates the bottleneck at the “End-of-Line,” ensuring that your high-speed secondary packaging machines can run at full capacity without pausing for downstream backups.

Robotic Palletizing Systems.

3. Solving the Labor Shortage Crisis

The manufacturing sector is facing a global labor shortage, particularly for repetitive, physical tasks like palletizing.

- Reliability: Robots don’t call in sick, take unexpected breaks, or quit for a competitor.

- Safety: Palletizing requires constant bending, lifting, and twisting. This is a leading cause of workplace injuries (Repetitive Strain Injury). By automating this process, you protect your workforce and reduce liability, shifting human employees to more valuable supervisory roles.

4. Flexibility for Multiple SKUs

In the tissue market, variety is key. A single production line might need to switch from 4-packs of toilet paper to jumbo rolls of kitchen towels or boxed facial tissues in the same day.

- Quick Changeover: Traditional mechanical palletizers are bulky and hard to reconfigure. A Palletizer Robot, however, is software-driven. Switching between different stacking patterns or box sizes can often be done with the touch of a button on the HMI (Human-Machine Interface), significantly reducing downtime during product changeovers.

5. Maximizing Warehouse Space

Robotic palletizers are known for their precision. They stack pallets tighter and straighter than manual labor ever could.

- Stability: A perfectly stacked pallet is more stable during transport, reducing product damage during shipping.

- Height: Robots can stack higher than humans (who are limited by reach), allowing manufacturers to utilize the full vertical space of their shipping trucks and warehouse racks.

For tissue manufacturers, the question is no longer if they should automate, but when. Integrating a Palletizer Robot into your line is the most effective way to secure your production capacity against labor shortages and rising costs.Suny specializes in advanced packaging solutions tailored for the tissue industry. Contact us today to design a robotic palletizing solution that fits your specific floor plan and production goals.