In today’s fast-paced manufacturing world, efficiency is the key to success. Case packing and palletizing lines have emerged as vital solutions for automating packaging and distribution processes. These systems combine advanced machinery to streamline the packaging of products, reduce human error, and increase production rates. If you’re in the manufacturing industry or looking to understand how these lines work, this guide will explain everything you need to know—from case packing machines to robotic palletizers and more.

What is a Case Packing and Palletizing Line?

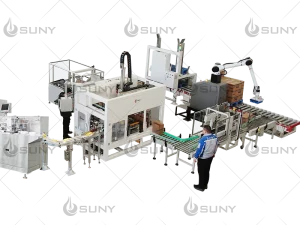

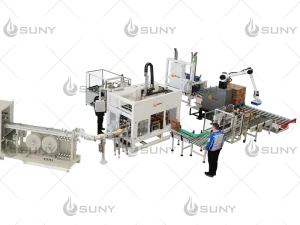

At its core, a case packing and palletizing line is a fully automated system designed to package and arrange products in preparation for shipping. The system works seamlessly by utilizing various machines, such as carton erectors, case packers, carton sealing machines, pallet auto feeders, and palletizer robots. Each of these machines performs a specific task, making the packaging process faster, more reliable, and scalable.

- Carton Erector: The first step in the process is to prepare the packaging. A carton erector forms flat, pre-scored cardboard into a rigid carton that can hold the products. The machine folds and glues the box, preparing it for packing.

- Case Packer: The case packer automatically arranges and inserts products into the prepared cartons. Depending on the machine’s design, it can handle a variety of products, from bottles to boxes, and place them into the cases with high precision.

- Carton Sealing Machine: Once the products are packed, the next step is to seal the carton. The carton sealing machine applies adhesive or tape to secure the box, ensuring that the contents remain intact during transport. This step is essential for preventing damage and ensuring security.

- Automatic Pallet Feeder: After cartons are sealed, they need to be arranged on pallets. The automatic pallet feeder automatically and independently pushes pallets to the loading area. This machine helps streamline the process from packaging to storage, reducing labor and improving efficiency.

- Palletizer Robot: Finally, a palletizer robot takes over the task of stacking the cartons onto pallets in a systematic, stable manner. These robots use precise motions to create compact and uniform pallet loads, which are ready for shipping. The robots can work at high speeds, making them a valuable addition to high-volume operations.

case packeing palletizing lines

FAQ

1. How do case packing and palletizing lines improve production efficiency?

These automated lines drastically reduce the time it takes to package and palletize products. Machines like the case packer and palletizer robot operate at faster speeds and with greater precision than humans, minimizing errors and maximizing throughput. As a result, companies can produce more products with fewer resources, lowering operational costs.

2. Are case packing and palletizing lines customizable?

Yes! Modern systems can be tailored to meet the specific needs of a manufacturing line. Whether you need to pack fragile products, irregularly shaped items, or items of various sizes, you can choose equipment that suits your production requirements.

3. What industries benefit the most from case packing and palletizing lines?

Industries that rely heavily on packaging, such as food and beverage, pharmaceuticals, and consumer goods, benefit the most from these lines. Companies in these sectors often deal with high volumes and strict regulations, making automation crucial for maintaining efficiency, safety, and consistency.

4. What are the maintenance requirements for these systems?

While case packing and palletizing systems are designed for high uptime, regular maintenance is essential to ensure they run smoothly. Most systems require periodic cleaning, lubrication, and inspection of parts like belts, motors, and sensors. Having a proactive maintenance schedule can prevent costly downtime and repairs.

Key Benefits of Case Packing and Palletizing Lines

- Increased Speed and Efficiency: Automation speeds up the entire packaging and palletizing process, significantly increasing production capacity.

- Reduced Labor Costs: By eliminating the need for manual labor in packing and palletizing, companies can lower labor costs and allocate resources more effectively.

- Enhanced Safety: These systems reduce the risks associated with manual labor, such as repetitive strain injuries and accidents on the production floor.

- Better Consistency: Machines deliver consistent results with precise carton dimensions, packing arrangements, and pallet configurations.

- Higher Flexibility: With the ability to adjust to various product sizes and shapes, automated systems can handle a wide range of packaging tasks, making them versatile for various industries.

Case packing and palletizing lines are game-changers in the manufacturing and packaging industries. By utilizing advanced machines like carton erectors, case packers, sealing machines, pallet feeders, and robotic palletizers, companies can achieve higher productivity, lower costs, and better-quality products. As demand for faster and more reliable production grows, investing in these systems is no longer a luxury but a necessity for staying competitive in today’s market.