In today’s fast-moving manufacturing world, efficiency isn’t just an advantage—it’s survival. Whether you’re in food processing, pharmaceuticals, home goods, or personal care products, case packing and palletizing lines have become the backbone of modern automation.

What Is a Case Packing and Palletizing Line?

A case packing and palletizing line is a fully or semi-automated system that performs two critical end-of-line operations:

- Case Packing: Products are packed into secondary cartons or cases using robotic or mechanical systems.

- Palletizing: Filled cases are then stacked systematically onto pallets for storage or shipment.

Together, they streamline production, reduce manual handling, and increase output efficiency—often by 30–60% compared to manual operations.

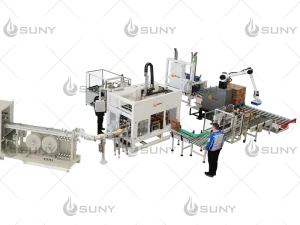

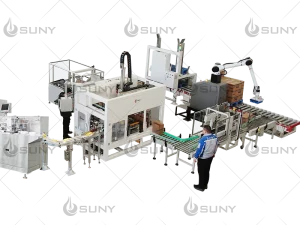

Case packing and palletizing line

Why Every Modern Factory Needs It

1. Consistency & Precision

Manual packing often leads to variation in box arrangement and pallet stability. A robotic or automatic case packer ensures every box is aligned perfectly—no more leaning pallets or crushed boxes.

2. Labor Cost Reduction

With increasing labor shortages and higher wages globally, automation pays off fast. Studies show ROI within 12–18 months for most installations.

3. Space Optimization

Compact modular designs save up to 40% of floor space, crucial for facilities with limited room.

4. Increased Throughput

High-speed lines can pack and palletize up to 40–80 cases per minute, depending on product size and type.

5. Enhanced Safety

By reducing manual lifting and repetitive motion, workplace injuries drop significantly.

Key Components of a Case Packing and Palletizing Line

A complete system typically includes:

- Infeed Conveyor System: Transfers products from the production line.

- Case Erector: Automatically forms and seals cartons.

- Case Packer: Loads products into cases (top-load, side-load, or wrap-around styles).

- Case Sealer: Seals the top and bottom flaps securely.

- Labeling & Inspection Station: Applies barcodes, checks weights, and ensures traceability.

- Robotic Palletizer: Arranges sealed cases onto pallets using programmed stacking patterns.

- Pallet Wrapper or Strapper: Stabilizes the load for transport.

Each element is customizable, ensuring flexibility for different product types, packaging formats, and speeds.

Frequently Asked Questions (FAQs)

1. What types of products can a case packing and palletizing line handle?

Almost anything—bottles, pouches, cartons, bags, jars, or cans. Industries like food & beverage, chemicals, wipes, and personal care use these lines extensively.

2. Can small factories benefit from automation?

Absolutely. Compact robotic palletizers and semi-automatic packers are now available for SMEs, offering scalable automation without massive investment.

3. How customizable are these systems?

Highly customizable—gripper types, case patterns, pallet configurations, and software interfaces can all be tailored to your specific product and workflow.

4. What about maintenance and downtime?

Modern systems come with remote diagnostics, predictive maintenance alerts, and smart sensors that minimize downtime by identifying issues early.

Investing in a case packing and palletizing line is not just about replacing people—it’s about unlocking performance. From improved product handling to reduced costs and safer workplaces, the benefits are undeniable.

As consumer demand rises and production cycles shorten, those who embrace automation early will dominate their markets. Whether you’re upgrading an old system or starting from scratch, now is the time to rethink how you pack, stack, and ship.

Automation doesn’t just change your process—it transforms your entire business trajectory.