Imagine this: your pillow packaging machine is running smoothly, producing perfectly sealed flow-wrap packs at high speed—yet your end-of-line process becomes a bottleneck. Operators struggle to manually load products into cartons, mistakes pile up, and your production loses momentum. So here’s the real question decision-makers are asking: Can a case packer line be seamlessly integrated with a pillow packaging machine? The short answer? Yes—and when done correctly, it can dramatically boost your efficiency, accuracy, and profits.

How the Integration Actually Works?

A pillow packaging machine, often called a flow wrapping machine, wraps products in sealed film at high speed. A case packer line automatically groups these wrapped products and loads them into cartons or cases.

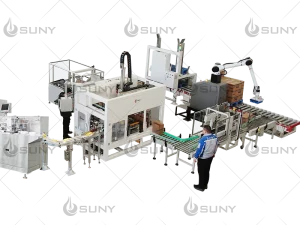

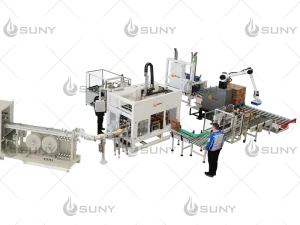

When integrated, the workflow becomes:

- Product is pillow-wrapped at high speed

- Automatic counting and grouping system organizes packs

- Robotic or mechanical case packer loads them into cartons

- Carton sealing and labeling happen automatically

This creates a continuous, fully automated packaging line with minimal human intervention.

case packer line

Why Manufacturers Are Switching to Integrated Systems?

The push toward automation is no longer optional. According to industry manufacturing reports, automated packaging lines can improve productivity by up to 40% and reduce labor costs by 25–30%.

Here’s what integration delivers:

✅ Faster throughput

✅ Fewer handling errors

✅ Improved hygiene

✅ Stronger package consistency

✅ Lower long-term operating costs

In highly competitive markets such as food, medical, and consumer goods, this advantage is game-changing.

Frequently Asked Questions (FAQ)

1. Can any pillow packaging machine be connected to a case packer line?

Yes, but compatibility matters. Machines must be synchronized through PLC controls, sensors, and conveyors. Most modern machines support integration, while older systems may require upgrades.

2. Will integration slow down my pillow packaging machine?

No. In fact, when properly synchronized, the case packer line removes downstream bottlenecks, allowing your pillow packing machine to run at optimal speed without interruptions.

3. Is the integration suitable for high-speed production?

Absolutely. High-speed case packer systems combined with servo-driven flow wrappers can reach 120–300 packs per minute, making them ideal for large-scale operations.

4. What products benefit most from this integration?

Popular applications include:

Snacks and confectionery

Biscuits and bakery products

Medical supplies

Wet wipes and tissues

Hardware items

These products demand clean, precise, and fast secondary packaging.

So, can a case packer line be integrated with a pillow packaging machine?

Not only can it be done—it has become a strategic necessity for modern factories. The integration delivers faster production, reduced costs, higher accuracy, and a calmer, more controlled manufacturing environment.

If you’re serious about growth, efficiency, and competitive advantage, this integration is no longer a luxury—it’s a must-have.