In today’s hyper-competitive manufacturing world, secondary packaging is no longer a back-end afterthought. It’s a profit lever, a brand protector, and a scalability test. As labor costs rise, SKU complexity explodes, and delivery timelines tighten, manufacturers are asking one urgent question:

How can we pack faster, smarter, and more reliably—without sacrificing flexibility?

That’s where the Chinapack Intelligent Secondary Packaging Machine steps in.

Designed for speed, precision, and future-ready automation, Chinapack’s intelligent solutions are transforming how factories handle case packing, bag-in-bag systems, and end-of-line automation. In this article, we’ll break down what makes Chinapack different, answer real buyer FAQs, and show why now is the time to upgrade.

What Is a Chinapack Intelligent Secondary Packaging Machine?

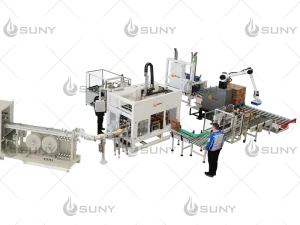

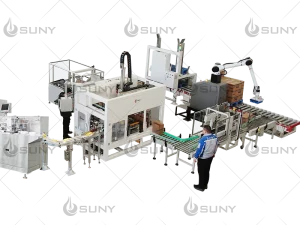

At its core, a Chinapack intelligent secondary packaging machine is an automated system that groups, packs, and prepares products for storage or shipping—typically into cartons, cases, or bags.

But unlike traditional machines, Chinapack systems are:

- servo-driven

- Highly modular and configurable

- Designed for multi-product, multi-format lines

- Integrated seamlessly with robotic palletizers

Think of it not as a single machine—but as a scalable packaging ecosystem.

7 Powerful Advantages of Chinapack Intelligent Secondary Packaging Machines

1. High-Speed Automation That Cuts Labor Costs Fast

According to industry data, secondary packaging automation can reduce labor costs by 30–50%. Chinapack machines operate at high cycle speeds with minimal human intervention, allowing factories to:

- Reassign workers to higher-value tasks

- Reduce dependency on skilled labor

- Maintain output even during labor shortages

👉 Result: Lower OPEX, higher consistency, faster ROI.

2. Unmatched Flexibility for Multi-SKU Production

One of the biggest pain points manufacturers face is frequent product changeovers.

Chinapack solves this with:

- Quick-change tooling

- Recipe-based HMI control

- Servo-driven positioning instead of mechanical cams

Whether you’re packaging towels, wipes, food pouches, cartons, or bags, Chinapack machines adapt fast.

Changeover times can be reduced by up to 60%.

3. Intelligent Control Systems = Fewer Errors

Human error is expensive. Mis-packed cases, incorrect counts, damaged cartons—it all adds up.

Chinapack integrates:

- Vision inspection systems

- PLC + smart sensors

- Real-time fault detection

This ensures accurate counting, consistent packing patterns, and zero-miss cases.

📊 Studies show smart inspection can reduce packaging errors by up to 90%.

4. Compact, Modular Design That Grows With You

Space is money on the factory floor.

Chinapack’s modular architecture means:

- Smaller footprint than traditional lines

- Easy expansion as output grows

- Simple integration with existing conveyors and palletizers

You don’t need to overhaul your entire line—you upgrade intelligently, step by step.

5. Built for Global Standards and Export Markets

If you’re shipping globally, compliance matters.

Chinapack machines are designed to meet:

- CE standards

- ISO quality requirements

- International safety norms

This makes them ideal for export-oriented manufacturers targeting Europe, the Middle East, Southeast Asia, and beyond.

6. Seamless Integration With Robotic Palletizing

Secondary packaging doesn’t end at case packing.

Chinapack specializes in end-of-line integration, combining:

- Case packers

- Bag-in-bag systems

- Robotic palletizers

- Automatic pallet feeders

👉 The result is a fully automated, lights-out end-of-line solution.

7. Smart ROI That Makes Financial Sense

Automation isn’t just about technology—it’s about payback.

Typical Chinapack customers report:

- ROI within 12–24 months

- Increased line efficiency by 20–40%

- Reduced downtime through predictive maintenance

This is not a cost—it’s a competitive investment.

Frequently Asked Questions (FAQs)

Is suitable for small and medium factories?

Absolutely. Chinapack offers scalable solutions, from semi-automatic systems to fully robotic lines. You start where you are—and grow when ready.

What industries use Chinapack secondary packaging machines?

Common industries include:

- Food & beverage

- Wet wipes & hygiene products

- Towels & textiles

- Daily chemicals

- Industrial goods

How difficult is maintenance?

Chinapack designs for low maintenance and high uptime, using globally available components and intuitive HMIs.

Can it handle future product upgrades?

Yes. Modular design ensures future-proof flexibility for new SKUs and packaging formats.

In a world where speed, accuracy, and flexibility define winners, manual or outdated secondary packaging is a hidden bottleneck.

The Chinapack Intelligent Secondary Packaging Machine offers:

- Faster throughput

- Lower costs

- Higher consistency

- Scalable growth

If your goal is to future-proof your factory, this isn’t just an upgrade—it’s a strategic shift.