In today’s hyper-competitive wet wipes industry, manufacturers are under intense pressure to deliver faster, reduce labor costs, and maintain flawless packaging quality. Because of this, one question keeps popping up:

“Can a case packer line be integrated into a wet wipes production line?”

The short answer: Absolutely — and doing so can boost output by 30–60% while cutting labor costs dramatically.

But integration isn’t just about connecting two machines. It’s about creating a synchronized, intelligent, high-throughput ecosystem that handles everything from primary packaging to pallet-ready cases.

Can a Case Packer Line Be Integrated Into a Wet Wipes Line?

Yes — And It’s One of the Smartest Upgrades You Can Make

Integrating a case packer line into a wet wipes production line is completely feasible and widely adopted across modern wipe manufacturing plants. Whether you produce flow packs, canister wipes, jumbo rolls, or pocket wipes, automation technology today allows seamless downstream integration.

In fact, many factories achieve:

- Continuous 24/7 operation with minimal operators

- 30–50% labor reduction (one operator instead of four)

- Up to 98% packaging accuracy

- Higher consistency and reduced human error

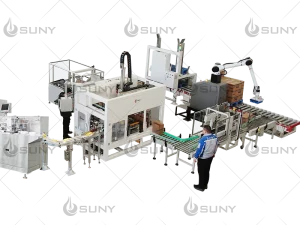

This is why global brands increasingly rely on fully integrated systems that combine wet wipes machines → conveyors → quality inspection → collators → case packers → palletizers.

Case Packer Line Be Integrated Into a Wet Wipes Line

Why Integration Works: The Core Functions

1. Automated Transfer from Primary Packaging

After wet wipes are sealed (typically 30–180 packs/min depending on machine size), automatic conveyors transport them directly to:

- Sorting modules

- Counting/stacking modules

- Robot pick-and-place units

- This ensures zero manual handling.

2. Intelligent Collation

Case packer lines can organize packs into:

- 2×3

- 3×4

- 4×5

- Custom retail-specific counts

This ensures SKU variability without machine replacement.

3. Robotic or Mechanical Case Loading

Depending on your investment level:

- Robotic case packers → higher speed, flexible, gentle handling

- Mechanical case packers → cost-effective, stable, ideal for uniform products

4. Automatic Case Sealing

Top or side sealers handle:

- Kraft cartons

- Shelf-ready packaging (SRP)

- Heavy-duty export cartons

5. Optional Palletizing

Integrating a palletizer means your production becomes a fully automatic end-of-line packaging system.

Frequently Asked Questions (FAQs)

1. What types of wet wipes can be integrated with a case packer line?

Most common formats:

- Baby wipes

- Cleaning wipes

- Disinfectant wipes

- Cosmetic wipes

- Industrial wipes

- Household wipes

- Travel pocket wipes

As long as the pack shape is consistent, integration is straightforward.

2. What production speeds can case packer lines handle?

Typical speeds:

- Standard wet wipes line: 30–120 packs/min

- High-speed wet wipes line: 150–180 packs/min

- Ultra-high speed lines: up to 300 packs/min

Today’s case packers can easily keep up.

3. What is the biggest benefit of integrating a case packer?

Automation eliminates manual labor, improving:

- Efficiency

- Cleanliness

- Accuracy

- Consistency

Plus, it reduces your dependency on skilled operators, which is a major problem in many factories.

If you want to upgrade efficiency, reduce labor dependency, increase consistency, and build a future-ready factory, then the answer is a clear yes.

Integration is no longer a luxury — it’s a competitive necessity.

A fully automated line is faster, smarter, more reliable, and more profitable. As SKU demands rise and labor costs continue increasing, manufacturers who integrate early will hold a powerful advantage for years.