In today’s hyper-competitive manufacturing landscape, factories face growing pressure to increase output, reduce labor costs, and maintain near-perfect product consistency. This has pushed companies to rethink how their packaging floors operate. One of the most common questions manufacturers ask is: “Can a case packer line be integrated with other packaging equipment?”

The short answer is yes — and in many industries, seamless integration has become the new standard. Whether you’re running a food plant, household goods line, personal care factory, or industrial packaging operation, integrating your case packer with upstream and downstream equipment can dramatically increase efficiency, accuracy, and throughput.

1. What Does It Mean to Integrate a Case Packer Line?

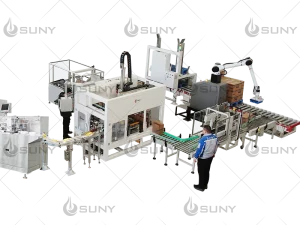

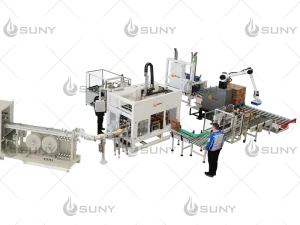

Integration simply means connecting your case packer to other machines so they work together as a smart, synchronized system.

This can include:

Primary packaging machines (flow wrappers, VFFS, HFFS, cartoners)

Conveying systems

Labeling and coding machines

Checkweighers and metal detectors

Palletizers and stretch wrappers

Automated warehouse systems (AGVs, AMRs, AS/RS)

Instead of operating independently, the machines “talk” to each other through PLC communication, allowing for automated speed control, product tracking, and error handling.

2. Why Integration Matters

1. Up to 40% higher throughput

Smooth product flow eliminates bottlenecks and idle time.

2. Labor cost reductions of 20–50%

Fewer operators are needed since machines share control logic.

3. Dramatically improved consistency

Automated, coordinated movements reduce human error and reject rates.

4. Faster changeovers

Integrated systems often use recipe-based control to switch SKUs in under 2 minutes.

5. Real-time monitoring

Plant managers gain instant visibility into OEE, downtime sources, and cycle speeds.

6. Better production planning

Stable, predictable upstream-downstream communication avoids overfeeding or underfeeding products.

Integration is not just convenient — it’s one of the fastest ways to scale operations without adding more floor space.

3. What Types of Packaging Equipment Can Be Integrated?

Case packers today support integration with nearly all modern packaging technologies. Here are the most common setups:

- Cartoners → Case Packers

Great for cosmetics, food pouches, pharmaceuticals.

- Baggers → Case Packers

Popular in snacks, grains, frozen foods.

- Filling & Capping → Case Packers

Bottle lines often integrate with robotic case packers for stability.

- Case Sealing Machines

- Checkweighers & X-ray Detectors

- Labeling & Barcoding Systems

- Robotic or Gantry Palletizers

- Automatic Pallet Dispensers

- Stretch Wrappers

So, can a case packer line be integrated with other packaging equipment? Absolutely — and doing so can transform your entire production floor. With higher throughput, lower labor costs, greater consistency, and the power of real-time data, integrated case packing lines are rapidly becoming the backbone of modern factories.